Inspired TEC

Inspired TEC Photocatalytic Oxidation & Ionization

Technology Overview

Inspired TEC Photocatalytic Oxidation (PCO) provides unique, state of the art environmental products to solve many of the biological, chemical and particulate problems faced in the indoor environment. We call our unique method of air purification Plasma, ionized gas, in recognition of the technologies ability to reach out and purify the entire environment, not just the air flowing through the device. We often use the analogy of taking the “Solution to the Pollution, versus the more traditional technologies such as filtration and ultraviolet germicidal inactivation (UVGI) which require the “Pollution to come to the Solution”. Plasma technologies include our unique Photocatalytic Oxidation (PCO) and Ionization process based upon technology used by NASA to purify the air in space, as well as 2 types of ionization.

Inspired TEC Photocatalytic Oxidation (PCO) provides unique, state of the art environmental products to solve many of the biological, chemical and particulate problems faced in the indoor environment. We call our unique method of air purification Plasma, ionized gas, in recognition of the technologies ability to reach out and purify the entire environment, not just the air flowing through the device. We often use the analogy of taking the “Solution to the Pollution, versus the more traditional technologies such as filtration and ultraviolet germicidal inactivation (UVGI) which require the “Pollution to come to the Solution”. Plasma technologies include our unique Photocatalytic Oxidation (PCO) and Ionization process based upon technology used by NASA to purify the air in space, as well as 2 types of ionization.

NASA Space Technology

Inspired TEC’s Photocatalytic Oxidation Technology has far reaching implications for health and safety. The technology consists of a proprietary Photocatalytic system using a combination of broad-spectrum high-intensity UV light and Titanium plus 3 additional rare metals bound in a hydrophilic base material. The result is a very effective system to safely purify the air and reduce microbial contamination on surfaces. The basis of this unique technology was developed at the University of Wisconsin and funded by NASA and the Center for Indoor Air Research (CIAR). NASA’s interest stemmed from a challenge with plant growth experiments. Plants give off ethylene gas, which builds up in the enclosed environment of the Space Station. Just like humans giving off carbon dioxide, which is harmful to human life at elevated levels, so is ethylene gas harmful to plants at elevated levels. The technology, a UV/Titanium Photocatalytic reactor, helped plants successfully grow to maturity on the Space Station. Inspired TEC has transformed NASA’s efforts into a commercial plasma and airborne/surface pathogen removal system, which also extends the life of perishable products.

This Photocatalytic system powered by ultraviolet light of 3 different wavelengths (broad-spectrum) takes oxygen and the natural humidity found in air enhanced to create a host of “Friendly Oxidizers”. These are oxidizers that are based on oxygen and hydrogen and revert back to harmless carbon dioxide and water after they oxidize. No chemicals are involved and therefore no chemical residue remains.

The main oxidizers created directly by the cell are:

- Hydroxyl Radicals (OH)

- Vapor Hydrogen Peroxide (H2O2)

- Super Oxides (O2-)

In addition, the system creates a non-thermal plasma (what we call Cluster Ions), which is equally as powerful as the oxidizers created by the system. These Cluster Ions, consisting of negatively charged oxygen and positively charged hydrogen, travels throughout the ventilated space, creating additional advanced oxidation products in the environment as well as inactivating through direct contact.

This state-of-the-art technology may be as significant an advance in infection control as the development of antibiotics. Inspired TEC’s Photocatalytic Infection and Mold Control Technology makes new infection control strategies possible, cost-effective, and efficient for government, businesses, medical facilities, educational institutions, mass transportation, and the hospitality industry.

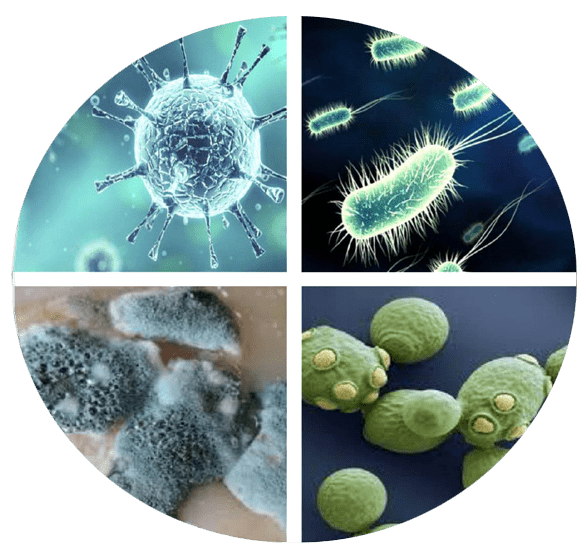

Photocatalytic technology has demonstrated the ability to safely disinfect each virus, bacteria, mold, and fungus against which it has been applied. Also, independent studies conducted by Kansas State University and the University of Cincinnati have proven this advanced oxidation process to be effective against the H5N8 Avian virus, Methycillin Resistant Staphylococcus Aureus (MRSA), Streptococcus, E-Coli, Listeria, Candida, Pseudomonas, Bacillus Subtilis, and Stachybotrys Chartarum (Black Mold). These University tests have shown that PCO technology can disinfect at least 96.4% and as much as 99.99% of surface-contaminating and airborne viruses and bacteria within the first 24 hours after installation.

Further, Dr. Marsden of Kansas State University had this to say based on his research: “After the first 24 hours exposure, any new microbe reduction is virtually instantaneous.”

Hydrogen Peroxide

One of the main oxidizers created by the Inspired TEC Photocatalytic Oxidation and Ionization Technology is Hydrogen Peroxide (H2O2), effective against microbes both in the air and on surfaces. Inspired TEC’s Photocatalytic Oxidation and Ionization Technology creates 0.02 parts per million (ppm) of hydrogen peroxide gas from the oxygen and humidity already in the air. The hydrogen peroxide gas is then supplied to the protected area where it diffuses everywhere air goes, disinfecting microbes in places that other technologies can’t even reach. The hydrogen peroxide molecules have both localized positive and negative charges; they are literally drawn to viruses and bacteria by electro-static attraction. Gram Positive and Gram negative Microbes don’t have much of a chance against the efficacy of the Inspired TEC’s photocatalytic systems.

The hydrogen peroxide gas is odorless and safe to use in occupied areas. According to OSHA, 1 part per million of hydrogen peroxide gas is safe throughout the workday. Inspired TEC’s Photocatalytic Ionization Technology uses one fiftieth of that amount. It has also shown that it can reduce ozone concentrations in incoming air. Hydrogen peroxide gas reacts with ozone to produce oxygen and water vapor.

Since most people have used hydrogen peroxide at one time or another to disinfect a cut or scrape, they should feel comfortable knowing that they can be protected by minute amounts of hydrogen peroxide gas in the air – just one hydrogen peroxide molecule for every ten million oxygen molecules.

Hydroxyl Radical

Another key oxidizer created by Radiant Catalytic Oxidation is the Hydroxyl Radical. The hydroxyl radical (OH) is an extremely aggressive oxidizer that neutralizes airborne contaminants and biological and chemical odors within milliseconds, converting them to harmless carbon dioxide and water vapor.

This hydroxyl radical is catalytically formed when broad-spectrum ultraviolet light with wavelengths of 185 nanometers, 254 nanometers and 375 nanometers in the presence of oxygen and water vapor combine with a titanium catalyst. Oxygen molecules are broken up into individual oxygen atoms that recombine with the hydrogen in the water molecules to form OHº. The OHº attacks carbon and hydrogen-based contaminants converting them to carbon dioxide or water.

Ultraviolet Germicidal Inactivation

In addition to the profound sterilizing effects of the hydroxyl radical and vaporous hydrogen peroxide, it should be noted that there is also a benefit provided by the ultraviolet light source, which powers the Photocatalytic reaction. Many studies have been done illustrating the sterilizing effects of 254-nanometer ultraviolet light. Food processing plants and hospitals have used UV light for many years to control environmental contamination. Also, UV light has been shown to control airborne tuberculosis, which recently has been making a comeback. We are also harnessing the beneficial effects of UV light by circulating the air to be treated by the UV light source.

UVc germicidal light has been used for decades in the medical and food industries to kill bacteria. While UVc light successfully kills bacteria, it only does so when it is in direct contact with the light rays, and UVc has little or no effect on odors. The combination of UVc light rays along with moisture and a Photo Catalyst creates a hydroxyl radical, which is even more powerful and many times faster than ozone as an oxidizer as well as vapor hydrogen peroxide. Extensive media investigations have shown that responsible deployment of hydroxyl radicals/Vapor Hydrogen Peroxide in occupied space (human and animal) will reduce the circulation and distribution of dangerous airborne contaminates.

Combination of UVc Light Rays & a Photo Catalyst to Create Hydroxyl Radicals, & Vapor Hydrogen Peroxide

Hydroxyl Radical/Vapor Hydrogen Peroxide injection is relatively simple. Depending on the application cubic area, a small 4 inch HVAC probe, or as much as a dual 14 inch HVAC probe is available.

HVAC (9 inch probe) can treat up to 16,000 cubic feet

In addition to the creation of Hydroxyl Radicals, Hydrogen Peroxide and low level Ozone, ions are emitted to aid in dust and ultra-fine particle removal. This process is known as “catalytic oxidation”. The free electrons emitted from the catalytic surface combine with oxygen and other molecules to create ions that attract and conglomerate particles.

Inspired TEC has tested the Photocatalytic Ionization Technology in numerous locations to assure the system will not generate ozone levels exceeding .04 ppm, with typical installations under .02 ppm.

Photocatalytic based HVAC units install in a matter of minutes. The first thing a duct-mounted unit does is sanitize the air ducts, which are often the source of disease and allergies in a facility because they are contaminated with viruses, bacteria, mold, and other fungi. Inspired TEC Photocatalytic systems are also more economical than competing technologies. A single cell duct-mounted unit designed to protect up to 40,000 cubic feet draws less than 25 watts (¼ amp) of electricity and requires maintenance only once every 24 months.

Inspired TEC’s Photocatalytic Technology is also fully scalable. More than half a dozen different configurations are already in production, from systems compact enough to protect a small room, or install in a self-contained heating and cooling unit.

Indoor air pollution is now ranked as the nation’s number 1 environmental health problem by the EPA and Congress. Sick building stories are commonplace, and asthma cases are increasing at an alarming rate. The need for safe, responsible indoor air purification technologies is real. Using Inspired TEC’s Photocatalytic Oxidation (PCO) is one of the preferred technologies.

Summary

The use of Inspired TEC’s Photocatalytic Ionization systems offers the following benefits:

- Increase yields

- Elimination of Gram positive and Gram negative bacteria

- Eliminate Gray mold, Botrytis, Blight, Powdery Mildew and Fungus

We breathe in approximately 23,000 times a day and intake 435 cubic feet of air per day. Wouldn’t it be nice if it was clean air!

Solutions for Environmental Hygiene (PDF)

John Hays Hammond

CEO, Inspired TEC LLC